High-Efficiency 3-Pass Steel Hot Water Boiler

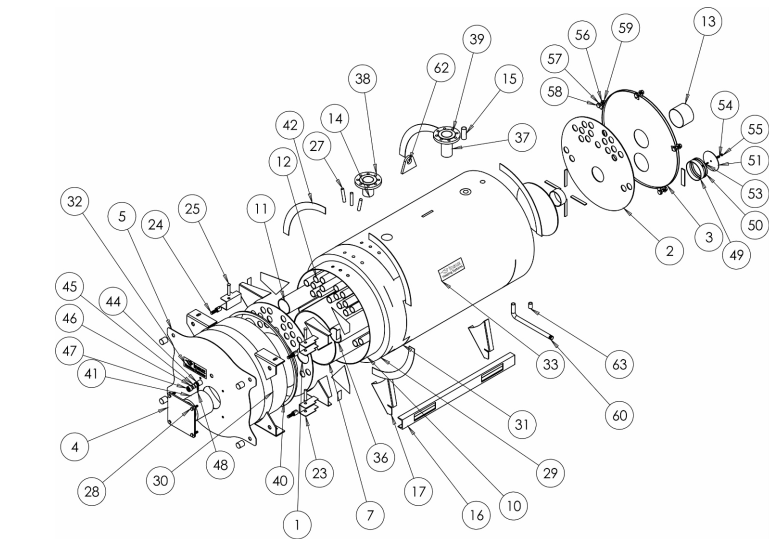

INSUZ PR is a three-pass, steel, flame-smoke tube hot water boiler with a fully sealed combustion chamber.

Designed with high technology, reliable modern engineering, and durable construction, it ensures high efficiency and long service life for heating industrial facilities and residential areas.

🔹 Capacity Range: 370 kW – 847 kW

🔹 Maximum Operating Pressure: 6 bar (0.6 MPa)

🔹 Maximum Operating Temperature: 110°C

🔹 Fuel Types: Natural Gas, LPG, CNG, Diesel, Fuel Oil

🔹 Boiler Efficiency: Up to 91%

⭐ For special orders or project-specific requirements, production up to 12 bar is available.

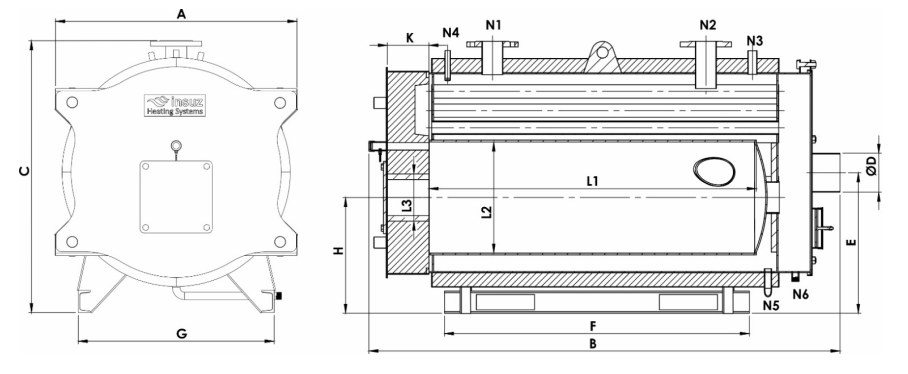

INSUZ PR Model Cross-Section and Connection Dimensions

In the technical drawing, the internal structure of the INSUZ PR series boilers is shown in detail..

This sectional view allows for a technical evaluation of the positioning and structural features of the boiler components

⚠️Burner compatibility should be evaluated by considering the combustion chamber dimensions and other parameters in the technical table. Additionally, ensure that the burner flame head length is correctly chosen according to the boiler door thickness.

⚠️ The Model Section and Connection Dimensions table is only visible on desktop devices. It is not supported on mobile devices.

INSUZ PR Model Technical Specifications

The technical table provides a detailed overview of the performance and operational parameters of the INSUZ PR series boilers.

This table includes essential technical data such as nominal capacity, efficiency rates, and operating pressure values. When selecting a burner and designing the piping system, factors like combustion chamber back pressure and water-side pressure losses should be considered. Additionally, maximum operating pressure and water capacity play a crucial role in system design.

To optimize your boiler’s performance, pay close attention to the technical specifications when making a selection.

For more information or assistance in choosing the right product, feel free to contact our team. We are here to provide you with the best solution!

⚠️ The Model Technical Specifications table is only visible on desktop devices. It is not supported on mobile devices.

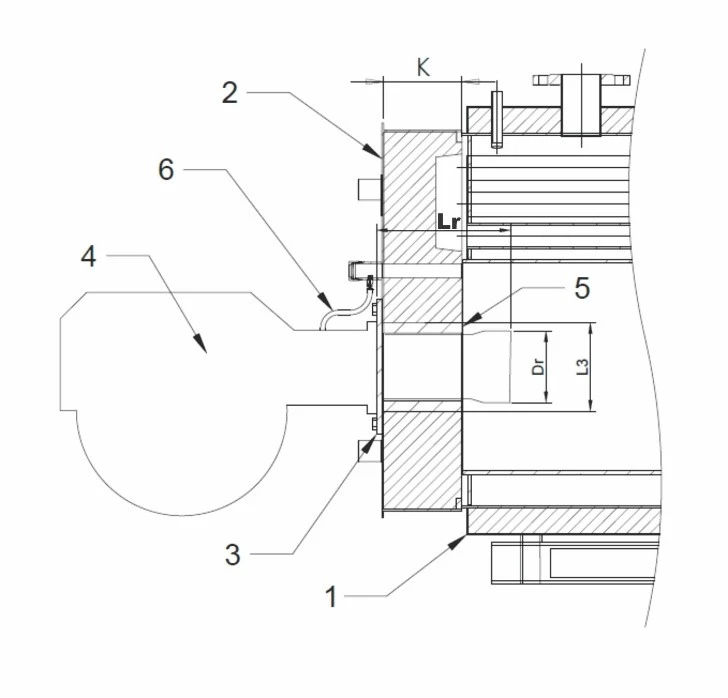

Burner Connection Details

⚠️ The Burner Connection table is only visible on desktop devices. It is not supported on mobile devices.

1- Boiler, 2- Boiler front door, 3- Burner mounting flange plate, 4- Burner, 5- Thermal insulation between the burner flame head and door, 6- Viewing Glass Cooling Air Supply Connection, K – Door Refractory Thickness, Lr – Burner flame head length, L3 – Front Door Opening Diameter Dr – Flame head diameter

⚠️ Lr > K ⚠️ Lr must be greater than K to ensure proper burner positioning.

For proper burner installation, the flame head length (Lr) must be greater than the cover insulation thickness (K). Otherwise, the burner cannot be properly positioned in the combustion chamber. Before ordering a burner, share these values with the burner manufacturer to ensure a correct selection.

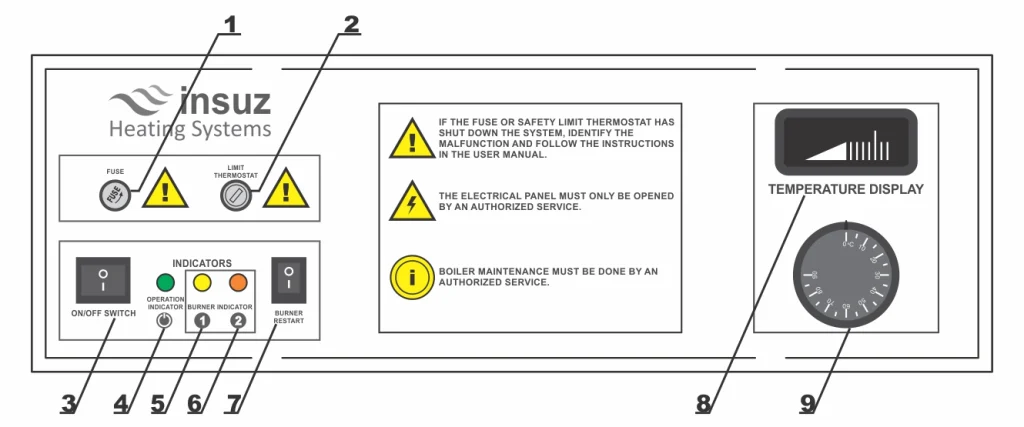

Boiler Control Panel

- Fuse

- Limit Thermostat (Manual Reset)

- On/Off Switch

- Operation Indicator

- First Stage Burner Indicator

- Second Stage Burner Indicator

- Burner Restart

- Temperature Display

- Setpoint Thermostat

INSUZ PR Model Hot Water Boiler Application Areas

Industrial Facilities

🔹 Food Industry: Industrial hot water boilers provide an efficient heat source for pasteurization and sterilization processes in food production. Large-scale hot water systems ensure continuous hot water supply for dairy and juice production. Industrial hot water boilers are used in process heating applications.

🔹 Textile Industry: Hot water systems for textile production are essential for dyeing, drying, and ironing processes. Industrial hot water boilers supply the necessary hot water for textile factories’ production lines. Energy-efficient hot water boilers support economic sustainability in the textile sector.

🔹 Chemical and Petrochemical Industry: Hot water boilers in chemical production processes enable precise temperature control for solvent evaporation and reaction processes. Hot water systems in petrochemical plants ensure stable and efficient chemical reactions. Industrial hot water solutions enhance energy efficiency in production, reducing operational costs.

🔹 Paper and Pulp Industry: Hot water boilers in the paper industry help maintain temperature balance in pulp preparation and paper drying processes. Hot water systems for pulp production provide controlled heating in manufacturing lines. High-efficiency hot water boilers in paper mills optimize energy consumption while accelerating production processes.

Large Commercial and Residential Applications

🏨 Hotels and Resorts: Hotel hot water boiler systems ensure uninterrupted hot water supply for guests. Hot water solutions in resorts provide 24/7 hot water for spas, swimming pools, and rooms. Centralized hot water boilers offer an economical and efficient solution for large-scale hospitality facilities.

🏥 Hospitals: Hygienic hot water systems in hospitals provide continuous hot water for sterilization, operating rooms, and patient rooms. Hot water boilers for medical equipment maintain the highest hygiene standards, ensuring safe usage. Centralized hospital hot water systems deliver energy-efficient and sustainable solutions for large buildings.

🏢 Shopping Malls and Large Buildings: Shopping mall hot water boiler systems supply constant hot water for stores, restaurants, and shared spaces. Hot water solutions for large buildings enhance comfort in commercial areas while improving energy efficiency. Hot water boilers for business centers integrate with HVAC systems to support centralized heating

🏫 Schools and Universities: Hot water boilers in educational institutions provide continuous hot water for classrooms, laboratories, cafeterias, and dormitories. School hot water systems ensure hygienic and efficient solutions for students and staff.

Heating Systems and District Heating

🏠 Central Heating Systems: Apartment hot water boilers distribute hot water evenly to residences through central systems, reducing individual heating costs. For large residential projects, central hot water solutions meet hot water demands efficiently, lowering maintenance and operational expenses. Energy-efficient hot water boilers operate with low fuel consumption, ensuring high performance in central heating systems.

🌍 District Heating: District hot water boiler systems provide collective heating solutions for cities, campuses, and industrial zones. Municipal hot water boilers offer an efficient and sustainable option for large-scale housing projects. Large-scale hot water systems enhance efficiency in communal heating applications, reducing carbon emissions.

Agriculture and Greenhouse Applications

🌿 Greenhouses: Hot water boilers for greenhouses maintain optimal temperature balance for plant cultivation. Cost-effective greenhouse heating solutions provide long-term savings with low energy consumption. The use of hot water in greenhouses supports healthy plant growth through soil heating and air circulation. Industrial greenhouse hot water boilers offer a reliable heating solution for large-scale agricultural production.

🐄 Livestock Farming: Barn and poultry house hot water boilers help maintain ideal temperature levels in animal shelters, enhancing productivity. Farm hot water systems ensure hygiene while reducing energy costs. Incubator hot water boiler solutions create optimal conditions for chick development. Industrial livestock hot water solutions provide continuous hot water supply for large-scale farms.

Русский

Русский Türkçe

Türkçe